Crafting precision stainless steel tanks for a spectrum of industries, BrewBilt Manufacturing delivers tailored solutions for beer brewing, wine making, food processing, chemical processing, life sciences, agricultural applications, solar steel platforms, and various building applications for outdoor kitchens, cabinets, gates, awnings and railings.

From enhancing fermentation processes to ensuring product integrity, our state-of-the-art vessels optimize efficiency and elevate quality across diverse manufacturing needs.

Trust BrewBilt Manufacturing for reliable, durable, and innovative solutions that redefine industry standards and maximize productivity.

Commercial Stainless Steel Fabrication

At Its Best

Premium Stainless Steel Craftsmanship.

Top-Quality Stainless Steel Products Custom Craft Breweries and other Beverage Industries

Innovative Stainless Steel Solutions for Agricultural and Food Processing

Custom Fabricated Metal Solutions for Chemical and Life Science Industries

Custom Solar Platforms for security, longevity and Strength

Custom railings and fences for commercial and residential aesthetics

Custom Awnings that will stand the test of time

Custom outdoor stainless steel full-service kitchen. No rust and no wear. Fits perfectly with your architecture.

Custom stainless steel cabinets that will last forever.

Custom stainless steel support frames for expensive retractable awnings that will provide better shade and structure

Custom laser-cut stainless steel signs and structures to withstand all weather.

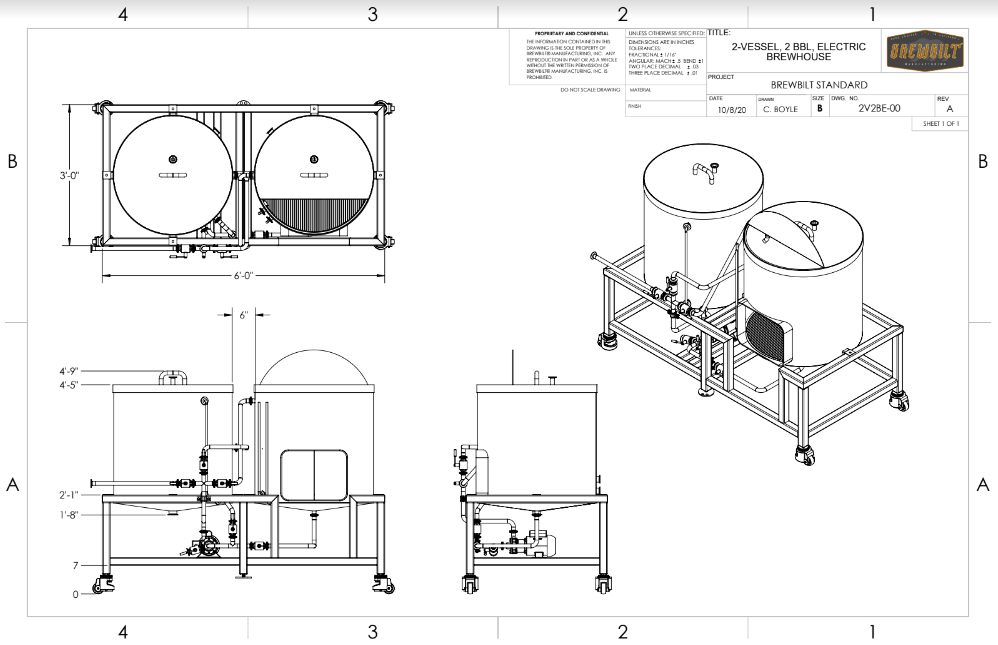

We offer small tanks for jobs that have space limitations

Our professional team works closely with you to determine the best outcome

We are here for you when you need a special design to accomplish your outcomes

No job is too big or too small as long as you maintain quality standards

We work with small and large companies to meet your budget

Creative engineering and design allows you space efficiency

Services

-

Our stainless steel fabrication services are expertly designed and crafted to meet your specific needs. From the cost-effective basic service to the comprehensive advanced service, we ensure that every detail is taken care of, resulting in top-quality stainless steel and metal works.

-

Our intermediate service offers a perfect balance of affordability and quality, providing you with precisely tailored metal fabrication solutions. Leave the details to us and experience our exceptional craftsmanship and attention to detail.

-

For the most intricate and demanding projects, our advanced service is the ideal choice. With our specialized steel and metal services, we bring your unique vision to life, ensuring immaculate precision and an exceptional end result.

Discover the art of steel fabrication

Explore the craftsmanship behind our stainless steel and metal works. From precision cutting to expert welding, we take pride in every detail of our process. Our passion and dedication shine through in every piece we create.

Discover our latest stainless steel works